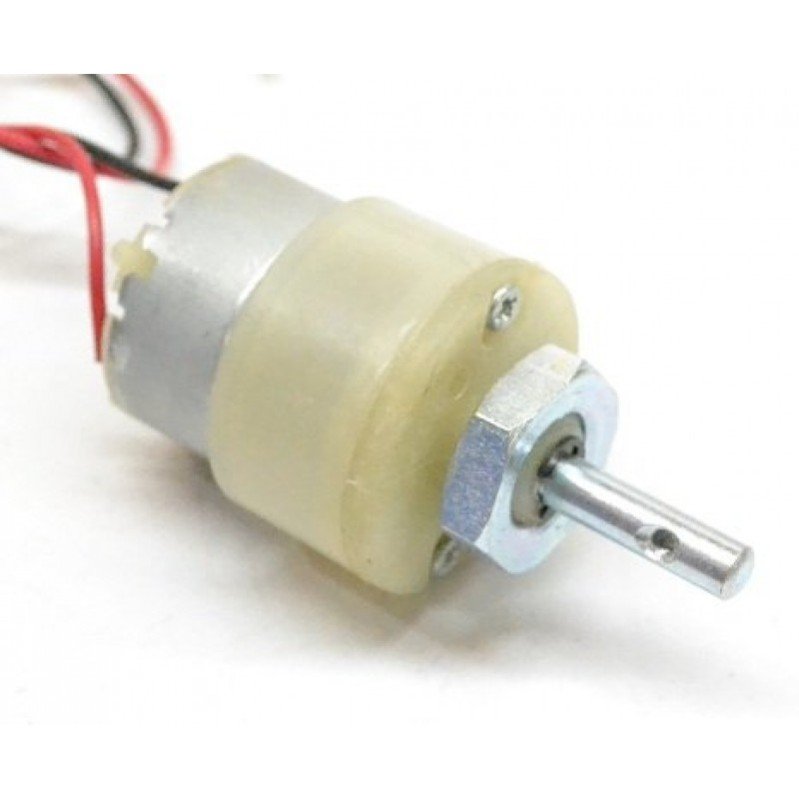

3.5RPM 12V Low Noise DC Gear Motor with Metal Gears – Grade A

The 3.5 RPM 12V Low Noise DC Motor with Metal Gears – Grade A is a high-quality, low-speed motor designed for quiet operation and durability. Operating at 3.5 rotations per minute, it is ideal for applications requiring precise, slow movement. Its metal gears ensure enhanced strength and longevity, making it perfect for robotics, model vehicles, and other precision tasks. With a 12V power supply, this motor delivers reliable performance while minimizing noise, making it suitable for noise-sensitive environments.

₹ 172

₹249

249

| : | |

| Made In : | India |

Add FAQ

The 3.5RPM 12V Low Noise DC Gear Motor (Grade A) is a compact and powerful gear motor engineered for low-speed, high-torque applications. Designed with hardened metal gears, it provides long operational life, superior wear resistance, and quiet performance.

This motor is ideal for:

-

Robotic arms

-

Smart door locks

-

Conveyor systems

-

Automated curtain openers

-

DIY model projects

-

Mini CNC or gear-driven mechanisms

Thanks to its reduction gear assembly, it outputs very low rotational speed (3.5 RPM) with sufficient torque for lifting or rotating mechanical components with precision. The low noise level and metal gear construction make it suitable for applications that demand quiet operation and durability.

Technical Specifications:

| Parameter | Specification |

|---|---|

| Operating Voltage | 12V DC |

| No-Load Speed | 3.5 RPM ±10% |

| Torque Output | ~20–30 kg·cm (varies by load) |

| Gear Type | Full metal gears |

| Noise Level | Low noise motor design |

| Motor Type | Brushed DC motor with gear reduction |

| Shaft Diameter | 6 mm (D-type or round, varies by model) |

| Shaft Length | Approx. 15–20 mm |

| Motor Body Length | Approx. 60–70 mm |

| Weight | ~150–180 grams |

| Direction Control | Reversible with polarity change |

| Mounting Holes |

Yes (standard tapped mounting holes) |

How to Use:

Wiring & Power:

-

Connect the +12V and GND wires to a regulated DC power supply or motor driver.

-

For direction control, reverse the polarity of the wires.

-

For Arduino/MCU use, connect via an L298N, L9110, or relay module for safe switching.

Typical Circuit Setup with L298N Motor Driver:

| Motor Wire | Connect To (L298N) |

|---|---|

| Red | OUT1 |

| Black | OUT2 |

| +12V Supply | VCC |

| GND | GND |

| ENA | PWM Pin (Arduino) |

| IN1, IN2 | Digital Pins (Arduino) |

Arduino Code:

int in1 = 7;

int in2 = 6;

void setup() {

pinMode(in1, OUTPUT);

pinMode(in2, OUTPUT);

}

void loop() {

digitalWrite(in1, HIGH);

digitalWrite(in2, LOW); // Motor rotates in one direction

delay(5000);

digitalWrite(in1, LOW);

digitalWrite(in2, HIGH); // Reverse direction

delay(5000);

}

Applications

- Hobbyist Robotics: For controlling precise movements in robots or other mechanical projects.

- Low-Speed Precision Mechanisms: For applications where slow, steady movement is essential, such as camera sliders, conveyor belts, or timers.

- Quiet Machines: Devices where minimizing noise is important, such as in quiet fans, pumps, or actuators.

This motor could be used in a wide range of applications where precision and low noise are required, and the metal gears will ensure it can handle the mechanical demands without failure.

0 Reviews For this Product